How to Achieve Unmatched Production Scale and Quality Assurance in Pen Manufacturing

In today's competitive global school supplies and office supplies market, achieving both large-scale production and impeccable quality is the holy grail for brands. For businesses looking to source or develop innovative writing pens, erasable pens, or magic pencils, understanding the backend manufacturing process is crucial. This white paper, drawing from the 25-year expertise of Kunshan Crystal Culture Co., Ltd. (Greenwill stationery), outlines a strategic framework for achieving unmatched production scale and quality assurance in pen factory operations.

Executive Summary

Scaling production without compromising on the performance of a ballpoint pen or the smoothness of a gel pen requires a holistic approach. It integrates advanced manufacturing technology, rigorous material science, full-process quality control, and a deep commitment to sustainability. This guide provides actionable insights for brands seeking reliable OEM/ODM partners to bring high-quality, innovative products like frixion erasable pens and infinite pencils to market efficiently.

Phase 1: Laying the Foundation – Strategic Planning & Design Integration

Before the first machine starts, a robust foundation is essential for scalable quality.

1.1 Deep Market Analysis & Conceptualization

Understand trends: The demand for custom pens, eco-friendly erase pens, and multi-functional pencils is rising. A partner like Greenwill stationery begins with analyzing global trends in school and office supplies to inform the design of products like their heat sensitive erasable gel pen or ergonomic comfortable grip pen.

1.2 Full-Process Design Service

From sketch to 3D model, ensure the design of your erasable ink pen or mini pen is optimized for manufacturability, user experience (UX), and cost-efficiency. This phase prevents costly revisions during mass production.

Actionable Tip: Choose an ODM partner that offers end-to-end design services, turning your brand idea for a friction pen into a viable, market-ready product.

Figure 1: Advanced assembly lines at the Greenwill stationery factory enable scalable production of diverse writing pens and pencils.

Phase 2: The Core of Scale – Manufacturing Excellence & Process Control

This is where strategic planning meets physical production.

2.1 Leveraging 25+ Years of Vertical Expertise

Deep expertise in specific categories—like erasable gel pens or non-sharpen pencils—allows for optimized processes. Kunshan Crystal Culture Co., Ltd. utilizes dedicated production lines for different product families, ensuring efficiency whether producing millions of ball pens or complex frixion pens.

2.2 Precision in Core Components

The heart of any writing pen is its ink and tip. Scale requires consistency. This is achieved through:

- Ultra-Precision Ball Tips: Sourced and tested to ensure every gel pen offers a smooth, skip-free writing experience.

- Custom Eco-Friendly Ink Formulations: Developed in-house for erasable ink pens and friction erasable pens to ensure long shelf life, consistent color, and reliable eraseability.

2.3 Automated & Flexible Production Lines

To achieve scale for products ranging from custom pen orders to standard office supplies, automation is key. The factory employs automated injection molding for pen barrels and assembly systems that can be quickly reconfigured for different pen models, supporting both large-scale and small-batch trial production.

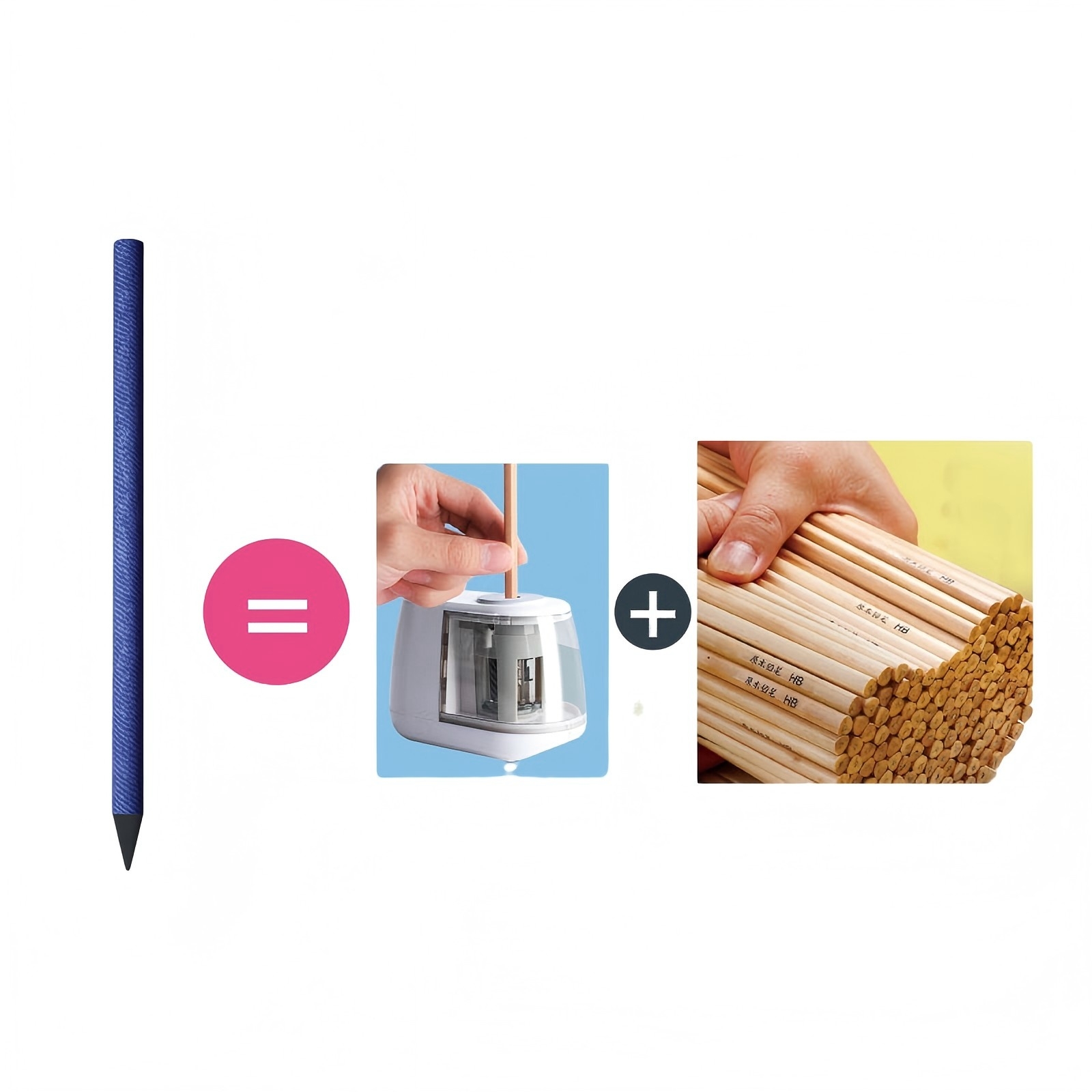

Friction Erasable Pen: A product of precise ink and tip engineering.

Inkless Pencil: Showcasing innovation in sustainable pencil drawing tools.

Phase 3: The Guardrails of Quality – Rigorous Assurance & Compliance

Scale means nothing without consistent quality. This is ensured through a multi-layered quality assurance (QA) system.

3.1 Full-Chain Quality Control

Quality is monitored at every stage: Incoming Material Inspection (e.g., TPR/TPE for erasers, alloy for tips) > In-Process Control (e.g., ink filling accuracy, tip assembly torque) > Finished Product Testing (e.g., writing length, erase performance of erase and rewrite pens, drop tests).

3.2 International Certifications & Standards

Adherence to global standards is non-negotiable for market access. A credible pen factory must hold certifications like: ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and ISO 45001 (Occupational Health & Safety). Compliance with EN71, REACH, PAHS, SVHC, and ASTM-D-4236 ensures products like erasable gel pens and magic pencils are safe for children and the environment.

Greenwill stationery Compliance Note: Our certifications, including FSC, BEPI, and the aforementioned ISO standards, provide our partners with the assurance that products like our everlasting pencil or school office ergonomic friction pen meet the highest global benchmarks for quality and responsibility.

3.3 Sustainable Manufacturing as a Quality Pillar

True quality now encompasses environmental impact. Implementing green manufacturing (energy conservation, waste reduction) and circular design (replaceable cores in non-sharpen pencils, recyclable materials) is essential. This aligns with the brand concept "Write the future, Erase worries away" and future-proofs your school supplies brand.

Phase 4: Partnership & Continuous Improvement

The journey doesn't end with delivery.

4.1 Collaborative OEM/ODM Models

Choose a partner that offers flexibility. Whether you need a completely custom frixion erasable pen design (ODM) or production of your existing ballpoint pen design (OEM), the partner should support joint development, mold customization, and scalable delivery.

4.2 After-Scale Support

A partner's value extends to post-production support, including logistics coordination, quality feedback loops, and collaborative innovation for the next generation of writing pens or endless pencils.

Conclusion: Scaling with Confidence

Achieving unmatched production scale and quality assurance is a systematic endeavor. It requires a manufacturing partner with proven expertise, integrated processes, an unwavering commitment to standards, and a vision aligned with market trends towards innovation and sustainability.

For brands seeking to launch or expand their lines of erasable pens, gel pens, infinite pencils, or other creative office supplies, partnering with an experienced manufacturer like Kunshan Crystal Culture Co., Ltd. (Greenwill stationery) provides a clear pathway. With over 25 years of experience, a full-service ODM/OEM model, and a portfolio trusted by global brands, they exemplify how scale and quality can coexist to build successful, reliable products in the competitive world of pen manufacturing.

Explore partnership possibilities and our innovative product lines at www.greenwillplus.com. Contact us at james@tinlongworld.com or +86-15151678868 to discuss your next project.